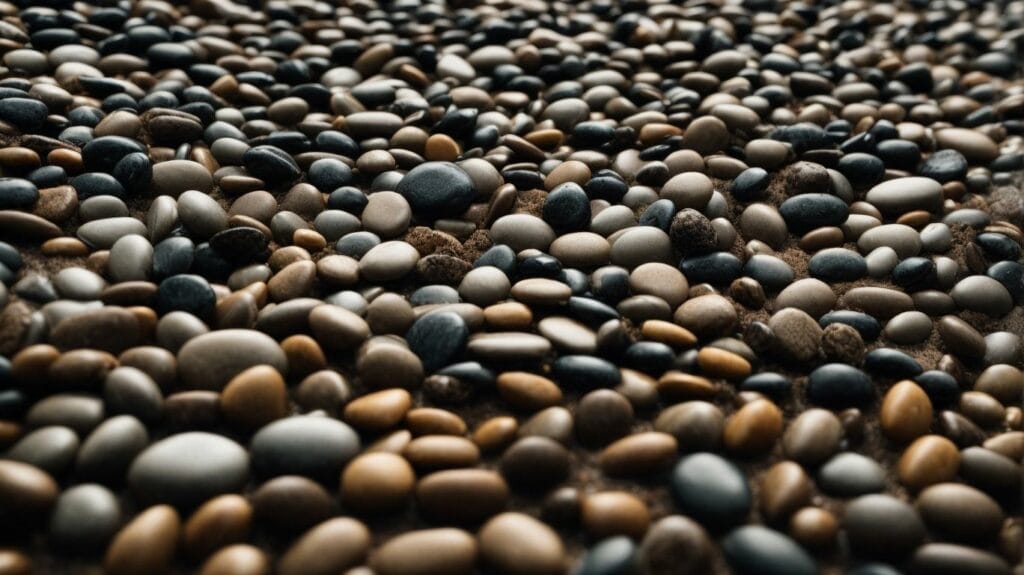

Epoxy stone is a type of flooring material made from a combination of small, smooth pebbles and epoxy resin. This creates a durable and versatile surface suitable for both indoor and outdoor use. It is often used for flooring in commercial and industrial spaces, as well as for outdoor areas such as pool decks and patios.

Epoxy stone is made by mixing epoxy resin and small stones or pebbles, often consisting of quartz, marble, or granite. The mixture is then applied to a prepared surface and left to dry and harden, creating a strong and durable surface.

Epoxy stone has a variety of uses, including:

- Outdoor flooring: It is commonly used for outdoor spaces such as driveways, walkways, and pathways.

- Pool decks: The non-slip surface of epoxy stone makes it a popular choice for pool decks.

- Patios and walkways: Epoxy stone provides a beautiful and durable option for outdoor areas that are constantly exposed to the elements.

- Garage floors: It is a great choice for garage floors as it is resistant to chemicals and oils.

- Commercial spaces: Epoxy stone is a popular choice for commercial spaces due to its durability and low maintenance.

- Industrial spaces: It is also commonly used in industrial spaces for its ability to withstand heavy machinery and high foot traffic.

The benefits of using epoxy stone include its durability, versatility, and easy maintenance. It is also slip-resistant, making it a safe option for outdoor areas. However, there are also some drawbacks to using epoxy stone, such as longer installation time, higher cost, and limited color options.

To install epoxy stone, the surface needs to be properly prepared by cleaning and repairing any cracks or holes. The epoxy resin is then mixed and applied to the surface, followed by spreading the stone chips evenly. Once the mixture has dried and hardened, the surface is sealed for added protection and shine.

Key Takeaways:

- Epoxy stone is a durable and versatile flooring option made from a mixture of epoxy resin and natural stone chips.

- It can be used in various spaces, such as outdoor areas, pool decks, patios, and even commercial and industrial spaces.

- While there are benefits such as durability and easy maintenance, drawbacks include longer installation time and higher costs compared to other flooring options.

What Is Epoxy Stone?

Epoxy stone is a type of flooring surface that is created by mixing small stones with an epoxy resin. This unique combination results in a highly durable and visually pleasing surface that is suitable for both indoor and outdoor use. Its strong resistance to stains, cracks, and abrasions makes it a popular choice for flooring needs.

Before choosing epoxy stone, it is important to consider factors such as foot traffic, exposure to the elements, and desired aesthetic. Seeking advice from a professional installer can also provide helpful guidance on the best approach for your specific requirements.

How Is Epoxy Stone Made?

- Preparation: To create epoxy stone, start by cleaning the surface and ensuring it is dry and free from any debris.

- Mixing: Next, combine the epoxy resin and hardener in the correct ratio and mix thoroughly.

- Adding Stone: Gradually add the stone aggregate to the epoxy mixture while continuing to mix.

- Application: Once the mixture is well-mixed, spread it evenly over the surface using a trowel.

- Curing: Finally, allow the epoxy stone to cure for the specified time, ensuring it hardens properly.

What Are the Uses of Epoxy Stone?

Epoxy stone is a versatile and durable flooring material that has become increasingly popular in recent years. Its unique composition of natural stones and epoxy resin creates a strong and attractive surface that can be used in a variety of settings. In this section, we will delve into the various uses of epoxy stone, from outdoor flooring to industrial spaces. Whether you are looking for a functional flooring solution or a visually appealing option, epoxy stone has you covered. So, let’s explore the many uses of this versatile material.

1. Outdoor Flooring

- Prepare the surface: Clear the area of any debris and ensure it is clean and level.

- Mix and apply the epoxy resin: Follow the manufacturer’s instructions for mixing the resin and evenly apply it.

- Add the stone chips: Sprinkle the stone chips onto the wet resin for a seamless finish.

- Seal the surface: Once the epoxy and stone mixture has been set, apply a sealant to protect the outdoor flooring from wear and tear.

For a successful outdoor flooring installation, meticulous surface preparation is crucial. In addition, it is important to apply the epoxy resin and stone chips evenly for a durable and visually appealing finish.

2. Pool Decks

- Prepare the surface by cleaning and repairing any damages.

- Mix and apply the epoxy resin over the pool deck area.

- Add the stone chips onto the wet epoxy surface.

- Seal the surface to protect the epoxy and stone chips from damage.

Fact: Epoxy stone pool decks provide a slip-resistant and durable flooring option, ideal for both residential and commercial pool areas.

3. Patios and Walkways

- Clear the area: Remove any existing debris, dirt, or old flooring from the patio or walkway.

- Prepare the surface: Ensure that the surface is clean, dry, and level before proceeding with the epoxy stone installation.

- Apply the epoxy resin: Mix and apply the epoxy resin onto the prepared surface, creating a strong and durable bond for your patios and walkways.

- Add the stone chips: Sprinkle the stone chips evenly onto the resin to achieve the desired texture and appearance on your patios and walkways.

- Seal the surface: Once the epoxy stone has cured, seal the surface to protect it from wear and tear on your patios and walkways.

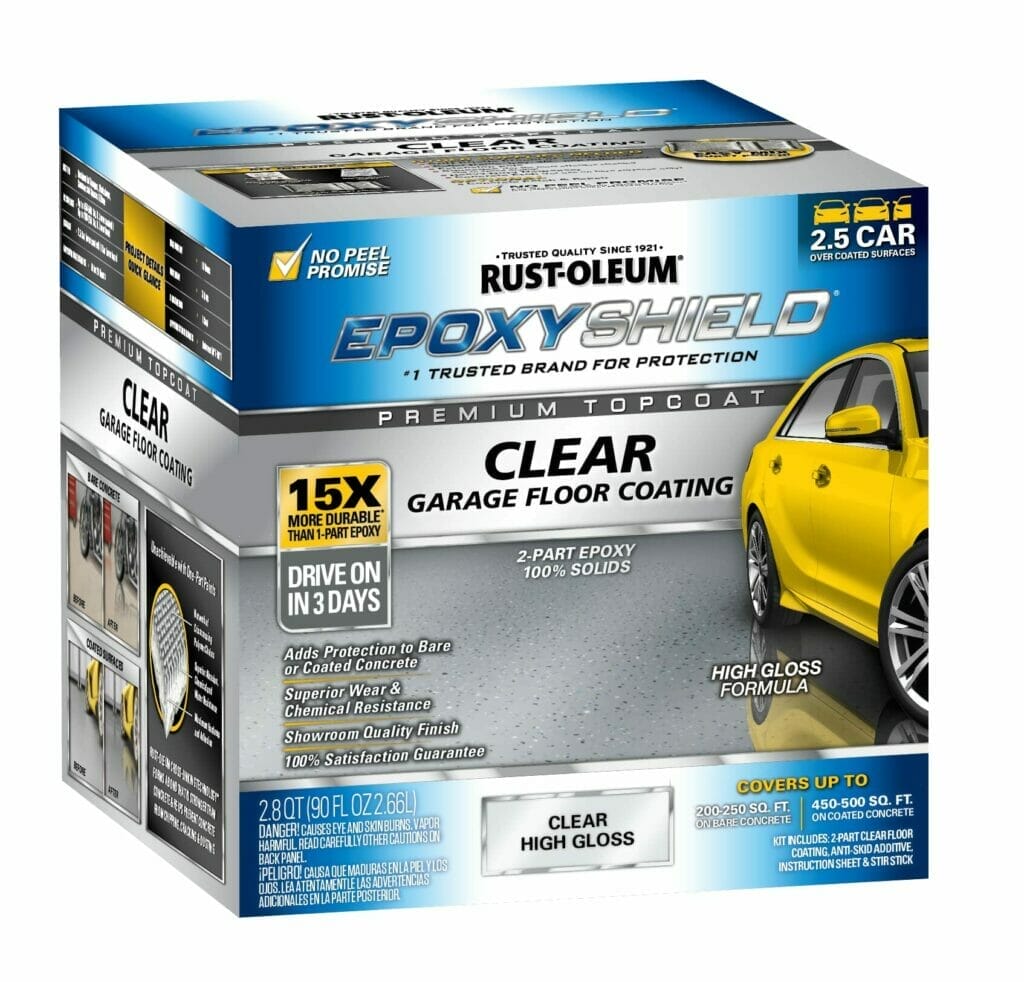

4. Garage Floors

- Before beginning, make sure the surface is clean and free of any debris.

- Follow the manufacturer’s instructions to mix and apply the epoxy resin.

- Evenly distribute the stone chips onto the freshly applied epoxy resin.

- For enhanced durability, seal the surface to protect the epoxy and stone chips.

For a long-lasting finish, it is important to carefully prepare the surface when installing epoxy stone on garage floors. Consider hiring professionals for optimal results.

5. Commercial Spaces

- Assess the space: Before beginning, it is important to evaluate the commercial area to determine the coverage area and any specific requirements for the project.

- Surface preparation: To ensure a successful application, it is crucial to thoroughly clean and prepare the surface, making sure it is smooth and free from any contaminants or debris.

- Mix and apply epoxy resin: Follow the manufacturer’s instructions for mixing and applying the epoxy resin, ensuring even coverage over the designated area.

- Add stone chips: To achieve the desired texture and coverage, evenly sprinkle the stone chips onto the wet epoxy resin.

- Seal the surface: Once the epoxy and stone chips are in place, apply a sealant to protect the surface and enhance its durability for commercial spaces.

6. Industrial Spaces

- Clean the industrial space thoroughly, removing any dirt, dust, or debris.

- Prepare the epoxy resin according to the manufacturer’s instructions, ensuring proper mixing and consistency.

- Apply the epoxy resin evenly onto the industrial floor, using appropriate tools for large areas.

- Add the stone chips to the epoxy resin, ensuring uniform distribution and coverage across the entire surface.

- Allow the epoxy stone mixture to cure and set properly, following the recommended time provided by the manufacturer.

- Seal the surface of the industrial space with a protective sealant to enhance durability and resistance in this type of environment.

What Are the Benefits of Epoxy Stone?

Epoxy stone is a popular flooring option that offers a wide range of benefits. In this section, we will discuss the various advantages of using epoxy stone in your home or business. From its durability to its slip-resistant properties, we will explore the unique benefits that make epoxy stone a top choice for many. So, let’s dive into the world of epoxy stone and discover why it is a favored option for flooring.

1. Durability

- Proper Surface Preparation: To ensure maximum durability of the epoxy stone application, make sure the surface is thoroughly cleaned, dried, and free of any contaminants.

- Thorough Mixing and Application: For a strong and long-lasting bond with the surface, it is important to mix and apply the epoxy resin accurately accurately.

- Evenly Adding Stone Chips: Enhance the durability and resistance of the flooring system by carefully adding the stone chips to the epoxy resin.

- Sealing the Surface: Increase the durability of the epoxy stone by sealing the surface with a high-quality sealant to protect it from wear and tear.

2. Versatility

Epoxy stone’s versatility is evident in its ability to be utilized on a variety of surfaces, including outdoor flooring, pool decks, patios, walkways, garage floors, and commercial and industrial spaces. This adaptability makes it a sought-after choice for a diverse range of applications.

Pro-tip: When considering epoxy stone for different surfaces, be sure to explore the custom color options available to match the aesthetic of the area perfectly.

3. Easy Maintenance

- Clean Regularly: Sweep or hose down the surface to remove debris and dirt.

- Use Mild Cleaners: For tougher stains, use a mild detergent and water solution to clean the epoxy stone surface.

- Avoid Harsh Chemicals: Refrain from using harsh chemicals or abrasive cleaners as they can damage the epoxy stone.

- Inspect Periodically: Keep an eye out for any damages or wear and tear, addressing them promptly to maintain the surface quality.

Pro-Tip: To make maintenance easy, apply a new seal coat every 2-3 years to preserve the appearance of your epoxy stone.

4. Slip Resistance

- Surface Texture: Epoxy stone provides a slip-resistant surface that is perfect for outdoor areas prone to water exposure.

- Safe Footing: The combination of stone and epoxy creates a secure footing, offering protection against accidental slips and falls.

- Weather Endurance: Its slip-resistant feature remains effective even in different weather conditions, ensuring safety all year round.

What Are the Drawbacks of Epoxy Stone?

While epoxy stone has gained popularity for its durability and versatility, it is important to also consider its drawbacks before choosing it as a flooring option. In this section, we will discuss the potential drawbacks of using epoxy stone, including its installation time, cost, and limited color options. By understanding these limitations, you can make a more informed decision about whether epoxy stone is the right choice for your flooring needs.

1. Installation Time

- Preparation of the Surface: Clean the surface thoroughly, repairing any cracks or imperfections.

- Mixing and Applying the Epoxy Resin: Follow the manufacturer’s instructions to mix the resin and apply it evenly to the prepared surface within the designated installation time.

- Adding the Stone Chips: Sprinkle the stone chips uniformly over the wet epoxy, ensuring full coverage and a consistent appearance.

- Sealing the Surface: Once the epoxy and stone chips are set, apply a clear sealant to protect the surface and enhance its longevity.

2. Cost

The process of installing epoxy stone includes a few necessary steps:

- First, it is important to estimate the square footage of the area that needs to be covered.

- Next, the surface must be prepared by thoroughly cleaning and repairing any cracks or damage.

- Then, the amount of epoxy resin and stone chips required must be calculated.

- Additionally, labor costs for mixing, applying, and sealing the surface should be factored in.

- It is also important to consider any extra expenses for color customization or special finishes.

Fun Fact: On average, the cost of installing epoxy stone flooring ranges from \$6 to \$10 per square foot.

3. Limited Color Options

- Explore custom color blends to expand your choices

- Consider alternative decorative techniques like staining or painting for more color options

- Consult with professional epoxy stone installers for color recommendations and to avoid limited color options

How to Install Epoxy Stone?

If you’re looking for a durable and unique flooring option, epoxy stone may be just what you need. But how exactly do you go about installing this type of flooring? In this section, we will break down the process into four simple steps. First, we’ll cover how to epare the surface for installation properly properly. Then, we’ll walk through the process of mixing and applying the epoxy resin. Next, we’ll discuss how to add the stone chips to create a beautiful and textured surface. Finally, we’ll go over the crucial step of sealing the surface to ensure a long-lasting and resilient finish.

1. Preparation of the Surface

- Thoroughly clean the surface to remove any dirt, grease, or debris.

- Repair any cracks or imperfections to ensure a smooth and even base.

- Etch the surface using an appropriate solution to promote better adhesion.

- Rinse the surface and make sure it is completely dry before proceeding with the epoxy stone installation.

Pro-tip: For best results, use a primer specifically designed for the surface material to enhance the bond between the epoxy and the substrate.

2. Mixing and Applying the Epoxy Resin

- Prepare the epoxy resin by following the manufacturer’s instructions to ensure proper mixing ratios and consistency.

- Mix and apply the epoxy resin by following these steps:

- Use a clean mixing container and thoroughly stir together the resin components, making sure to eliminate any streaks or inconsistencies.

- Evenly apply the mixed resin onto the prepared surface, working in small sections at a time, using a roller or squeegee.

- Make sure to spread the resin uniformly and smoothly to achieve a seamless and durable finish.

3. Adding the Stone Chips

- Clean the surface thoroughly to ensure proper adhesion of the epoxy.

- Mix the epoxy resin according to the manufacturer’s instructions and evenly apply it over the prepared surface.

- Gently spread the stone chips onto the wet epoxy, ensuring complete coverage and a consistent look.

- Allow the epoxy and stone chips to cure for the recommended time.

Stone chips not only enhance the appearance of the surface but also provide texture and traction for added safety.

4. Sealing the Surface

- Clean the surface thoroughly to remove any debris, dirt, or oils.

- Apply the epoxy sealer using a roller or brush, making sure to cover the entire surface.

- Follow the manufacturer’s instructions for drying time.

- If desired, apply a second coat for increased protection and durability.

For best results, it is recommended to seek the assistance of a professional when applying the epoxy sealer, ensuring a long-lasting and resilient surface.