Metallic epoxy flooring is a unique and modern flooring system that involves mixing metallic pigments with epoxy resin to create a marble-like effect. The result is a glossy, luxurious, and durable flooring option suitable for both residential and commercial spaces. This article will provide an overview of metallic epoxy flooring, its application process, benefits, and maintenance tips.

Metallic epoxy flooring is a type of decorative flooring that uses metallic pigments to create stunning and intricate designs on the floor. The metallic pigments, when mixed with epoxy resin, create a three-dimensional effect, giving the floor a unique and luxurious appearance. Metallic epoxy flooring is a popular choice for high-end homes, restaurants, retail stores, and other commercial spaces due to its aesthetic appeal and durability.

The application process of metallic epoxy flooring involves several steps. The floor surface is first prepared by cleaning, repairing any damages, and ensuring it is level. A primer is then applied to improve adhesion between the existing floor and the epoxy coating. Next, the metallic epoxy coating is applied in multiple layers, each with a different metallic pigment, to create a marbled effect. Lastly, a topcoat is applied for added durability and gloss.

One of the main benefits of metallic epoxy flooring is its aesthetic appeal. It offers a high-end and luxurious look that can elevate the overall design of a space. Moreover, metallic epoxy flooring is highly durable and can withstand heavy foot traffic, making it suitable for high-traffic areas. It is also resistant to chemicals and stains, making it a low-maintenance flooring option. Additionally, it is easy to clean and can last for many years if properly maintained.

There are various designs and finishes available in metallic epoxy flooring, making it a versatile option for different spaces. Some popular designs include solid colors, metallic marble, metallic pearl, and metallic flake. These designs can be customized to suit the specific design needs of a space, making metallic epoxy flooring a popular choice for interior designers and architects.

To prepare for a metallic epoxy flooring installation, the surface needs to be properly prepared. This involves cleaning the floor and repairing any damages, such as cracks or holes. A primer is then applied to ensure proper adhesion of the epoxy coating. The metallic epoxy coating is then applied in multiple layers, and a topcoat is added for added protection and gloss.

To maintain the beauty and durability of metallic epoxy flooring, regular cleaning is essential. Spills should be wiped up immediately, and the floor should be swept or vacuumed regularly to prevent dirt and debris from scratching the surface. It is also important to avoid using harsh chemicals on the floor and to use mats or rugs in high-traffic areas to prevent wear and tear. Any damages should be repaired promptly to prevent them from worsening.

Key Takeaways:

- Metallic epoxy flooring offers both aesthetic appeal and durability, making it a popular choice for residential and commercial spaces.

- The application process involves surface preparation, primer application, metallic epoxy coating, and topcoat application.

- Maintaining metallic epoxy flooring is simple, requiring regular cleaning, avoiding harsh chemicals, and promptly repairing any damages to maintain its shine and longevity.

What Is Metallic Epoxy Flooring?

Photo Credits: Diyepoxyresin.Com by Jordan Scott

Metallic epoxy flooring is a distinctive type of floor coating that utilizes metallic powder to achieve a striking, three-dimensional appearance. So, what exactly is metallic epoxy flooring? It is a long-lasting, personalized, and visually impressive option for both residential and commercial spaces. The metallic pigments blend and swirl together to create a glossy and seamless surface that resembles molten metal or marble, making it a favored choice for both decorative and high-traffic areas.

How Is Metallic Epoxy Flooring Applied?

Photo Credits: Diyepoxyresin.Com by Timothy Nelson

- Surface Preparation: Before applying metallic epoxy flooring, the concrete surface must be cleaned and prepared through methods such as grinding or shot blasting to ensure proper adhesion.

- Priming: A primer should then be applied to the prepared surface to enhance the bond between the concrete and the epoxy.

- Metallic Epoxy Application: The metallic epoxy resin should be mixed with metallic pigments and applied using a roller or squeegee to achieve the desired design and effect.

- Topcoat: To ensure added protection and durability, finish the metallic epoxy flooring with a clear topcoat.

What Are The Benefits Of Metallic Epoxy Flooring?

Photo Credits: Diyepoxyresin.Com by Ryan Walker

Metallic epoxy flooring has gained popularity for its unique and eye-catching appearance, but there are many other benefits to this type of flooring. In this section, we will discuss the various advantages of metallic epoxy flooring and how it can enhance both the look and function of a space. From its impressive durability to its low maintenance requirements, we will cover the many reasons why metallic epoxy flooring is a top choice for both residential and commercial spaces.

1. Aesthetic Appeal

- Color Play: The unique patterns and color combinations create a visually stunning and aesthetically appealing floor.

- Reflective Surface: The glossy finish of metallic epoxy flooring adds depth and dimension to the space, enhancing its overall aesthetic appeal.

- Customization: Various techniques like blending, marbling, or layering offer endless design possibilities, making the floor even more visually appealing.

- Light Enhancement: The floor’s reflective properties can brighten up the area, enhancing the overall ambiance and aesthetic appeal.

2. Durability

- High-Performance Coating: Metallic epoxy flooring is known for its exceptional durability, providing a long-lasting and robust surface.

- Impact Resistance: The epoxy coating creates a tough and impact-resistant flooring system, making it perfect for high-traffic areas and industrial settings.

- Protection Against Wear: It offers excellent resistance to wear and tear, maintaining its durability even in demanding environments.

- Chemical Resistance: The flooring is highly resistant to chemicals, preventing damage and ensuring long-lasting durability.

3. Low Maintenance

- Regular Cleaning: Use a gentle cleaner and a soft mop to clean the floor regularly to maintain its shine and appearance.

- Avoid Harsh Chemicals: Refrain from using strong chemicals or solvents that can damage the epoxy coating.

- Use Mats and Rugs: Place protective mats or rugs in high-traffic areas to prevent scratches and preserve the flooring.

- Repair Any Damages Promptly: Address any scratches or damages promptly to prevent further deterioration.

Pro-tip: For a low-maintenance option, consider applying a new topcoat every few years to rejuvenate the shine and protective qualities of the metallic epoxy flooring.

4. Chemical and Stain Resistance

Metallic epoxy flooring offers exceptional chemical and stain resistance due to its seamless nature, preventing liquids and chemicals from seeping into the floor. This makes it ideal for areas with high exposure to spills and stains, such as garages, laboratories, or industrial settings.

What Are The Different Designs And Finishes Available In Metallic Epoxy Flooring?

Photo Credits: Diyepoxyresin.Com by Brandon Jones

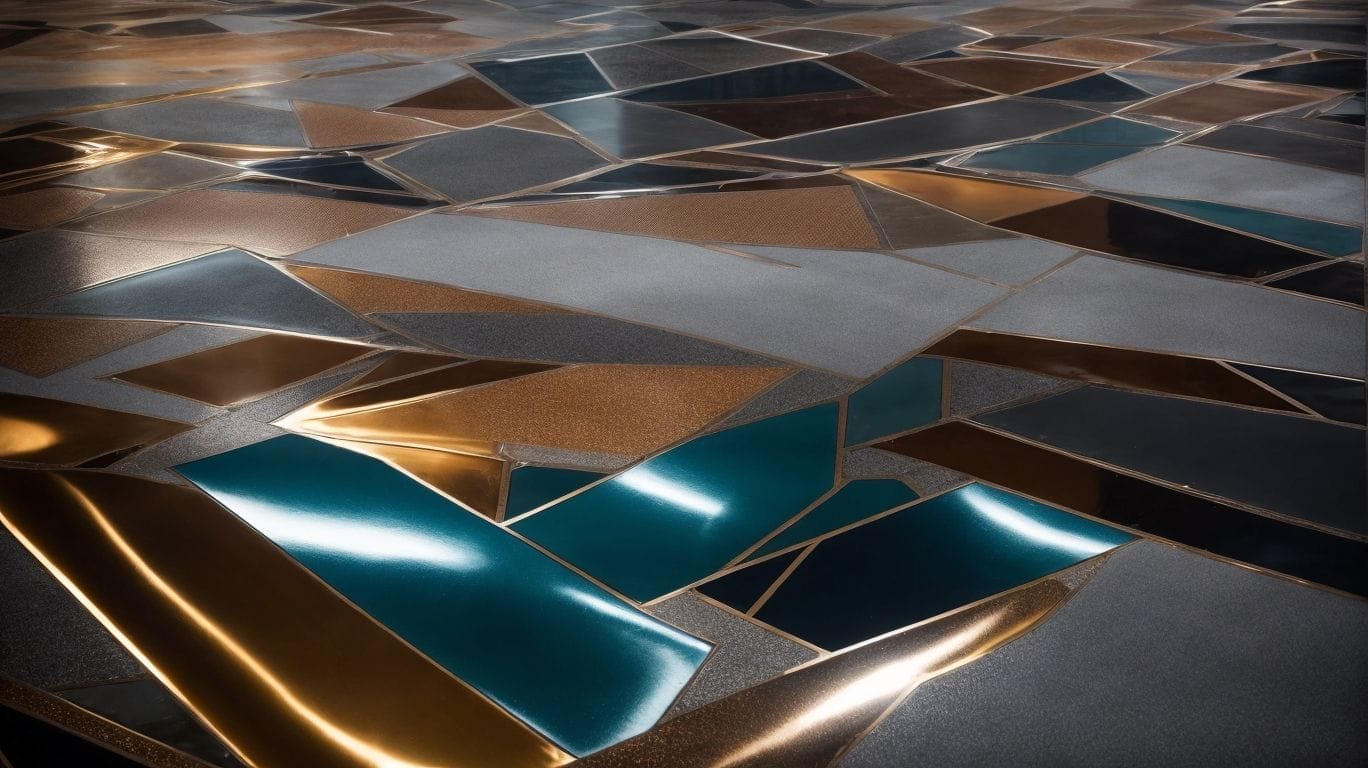

When it comes to metallic epoxy flooring, there are a variety of designs and finishes to choose from. Each one offers a unique aesthetic and can transform the look of any space. In this section, we will discuss the different types of designs and finishes available in metallic epoxy flooring. From solid colors to intricate marbling, pearlescent effects, and metallic flakes, there is a style for every taste and preference. Let’s explore the possibilities of metallic epoxy flooring and how it can enhance the appearance of your floors.

1. Solid Color

When choosing a solid color metallic epoxy flooring, the process typically involves the following steps:

- Surface Preparation: Thoroughly clean and prepare the surface to ensure proper adhesion.

- Primer Application: Apply a primer to improve the bond between the surface and the metallic epoxy.

- Metallic Epoxy Coating Application: Apply the metallic epoxy coating evenly to achieve the desired solid color effect.

- Topcoat Application: Finish with a topcoat for added protection and durability.

To achieve a seamless solid color finish, it is important to prepare the surface and apply the metallic epoxy precisely and meticulously.

2. Metallic Marble

- Prepare the Base: Begin by preparing the base floor with a primer and base coat, ensuring a smooth and even surface.

- Apply Metallic Marble Epoxy: Mix the metallic marble epoxy resin and hardener, then apply it over the base coat using a trowel or roller to create a stunning marble effect.

- Seal the Surface: Once the epoxy has cured, apply a clear topcoat to seal and protect the metallic marble finish.

- Maintain Regularly: Keep your metallic marble epoxy flooring looking its best by regularly cleaning it with a soft mop and gentle cleaner.

Pro-tip: When applying metallic marble epoxy flooring, make sure the room is well-ventilated to aid in the curing process and minimize any odors.

3. Metallic Pearl

Metallic pearl is a type of metallic epoxy flooring finish that utilizes pearlescent pigments to achieve a stunning and iridescent effect. This flooring option is ideal for enhancing the aesthetic of spaces like retail stores, hotels, or residential interiors with its unique and luxurious appeal. The shimmering and multidimensional appearance of metallic pearl flooring creates a captivating visual impact, making it a great choice for areas that require a touch of sophistication and upscale ambiance, such as luxury boutiques or high-end residential properties.

Pro-tip: For an elegant and upscale feel, consider incorporating metallic pearl epoxy flooring into your space.

4. Metallic Flake

Metallic flake is a highly sought-after design choice for metallic epoxy flooring, providing a breathtaking and multidimensional look. This design incorporates colorful flakes into the epoxy coating, giving the floor depth and texture. The reflective nature of the metallic flakes creates a dazzling and shimmering effect that elevates the overall visual appeal of the flooring.

What Are The Steps To Prepare For A Metallic Epoxy Flooring Installation?

Photo Credits: Diyepoxyresin.Com by Paul Carter

Before embarking on a metallic epoxy flooring installation, it is crucial to properly prepare the surface to ensure a flawless and long-lasting finish. In this section, we will discuss the step-by-step process of preparing for a metallic epoxy flooring installation. From surface preparation to the application of primer and metallic epoxy coating, we will guide you through the necessary steps to achieve a stunning and durable metallic epoxy floor. Let’s take a closer look at each stage to understand the importance and techniques involved in preparing for a successful installation.

1. Surface Preparation

Surface preparation for metallic epoxy flooring involves several crucial steps:

- Thoroughly clean the surface to remove any dirt, debris, or contaminants.

- Repair any cracks, holes, or imperfections in the existing floor to ensure a smooth substrate.

- Check for proper moisture levels in the concrete to prevent adhesion issues.

- Abrade or etch the surface to create a textured profile that will enhance epoxy adhesion.

Metallic epoxy flooring has gained popularity in recent years due to its seamless, high-gloss finish and versatility in design options.

2. Primer Application

- Prepare the surface: Make sure to clean the floor of any dust, debris, or previous coatings before beginning the primer application process.

- Fix any damages: Fill in any cracks or holes in the floor to create a smooth and even surface.

- Etch the floor: Use an etching solution to open up the pores of the concrete, allowing for better adhesion of the primer.

- Apply the primer: Use a roller or brush to apply the primer across the entire surface evenly.

The use of primers in floor coatings dates back to ancient civilizations, where natural substances were applied to prepare surfaces for decorative and protective treatments.

3. Metallic Epoxy Coating Application

- To prepare the surface, grind or shoot and blast it to remove any existing coatings or contaminants.

- Ensure proper adhesion between the substrate and epoxy coating by applying a primer.

- Using a roller or squeegee, evenly apply the metallic epoxy coating to create the desired design or pattern.

- Before adding the topcoat for added protection, allow the coating to cure according to the manufacturer’s instructions.

For a seamless application of metallic epoxy coating, make sure the substrate is clean and level. Follow the manufacturer’s guidelines for a successful and visually appealing finish.

4. Topcoat Application

- Clean the floor surface thoroughly to remove any dust, debris, or contaminants.

- Apply the primer to ensure proper adhesion of the metallic epoxy coating.

- Mix the metallic epoxy coating components and apply it evenly with a roller or squeegee.

- Allow the metallic epoxy coating to cure before applying the topcoat.

- For the final step, apply the topcoat to enhance the durability and protective properties of the metallic epoxy flooring.

A customer once requested a metallic epoxy flooring installation to transform their bland concrete floors. The result was stunning, with a glossy metallic finish that completely revitalized the space, impressing everyone who saw it.

How To Maintain Metallic Epoxy Flooring?

Photo Credits: Diyepoxyresin.Com by Mark Allen

Keeping your metallic epoxy flooring in pristine condition requires proper maintenance and care. In this section, we will discuss the essential steps to maintain your metallic epoxy flooring. From regular cleaning to avoiding harsh chemicals, we will cover the best practices to ensure your flooring retains its shine and durability. We will also touch on the importance of using mats and rugs to protect your flooring, as well as promptly repairing any damages that may occur. Let’s dive into the proper maintenance techniques for your metallic epoxy flooring.

1. Regular Cleaning

- To keep metallic epoxy flooring looking its best, regular cleaning is crucial.

- Begin by using a soft-bristled broom or dust mop to remove any loose debris.

- For mopping the floor, use a mild pH-neutral cleaner and water that is safe for metallic epoxy surfaces.

- Be sure to rinse the floor thoroughly to get rid of any residue, and dry it with a soft cloth or microfiber mop.

2. Avoid Harsh Chemicals

- When cleaning metallic epoxy flooring, it is important to avoid using strong acidic or alkaline products as they can damage the surface.

- Instead, opt for pH-neutral cleaners that are specifically formulated for maintaining epoxy flooring.

- Always follow the manufacturer’s guidelines for cleaning solutions and methods to ensure the longevity of your metallic epoxy flooring.

3. Use Mats and Rugs

- Place mats at entryways to trap dirt and prevent scratching.

- Use rugs in high-traffic areas to protect the floor from wear and tear.

- Opt for non-slip mats to enhance safety and prevent accidents.

- Regularly clean and shake out mats and rugs to maintain cleanliness and prevent debris from accumulating.

For best results, consider investing in high-quality, properly sized mats and rugs to preserve the beauty and longevity of your metallic epoxy flooring.

4. Repair Any Damages Promptly

- Assess the damage: Regularly inspect the flooring for cracks, scratches, or chips.

- Immediate action: Upon noticing any damage, promptly address it to repair it and prevent further deterioration.

- Repair process: Use appropriate epoxy repair kits or materials to fill in the damaged areas.

- Seal and protect: Apply a topcoat or sealant to the repaired areas to ensure longevity.